XL810

XL810 - real-time data for production and performance management

XL is the simplest, fastest, and most powerful way to monitor and improve manufacturing.

XL810 is a bolt-on smart device that includes onboard I/O to monitor your process.

It provides you with a scoreboard for a true visual factory, factory wide real time data and reports for managers to drive continuous improvement.

IoT that scales from machine to enterprise.

Monitor any machine. Anywhere.

Features

-

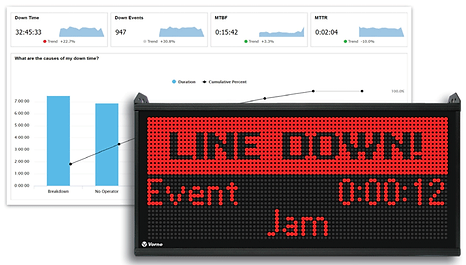

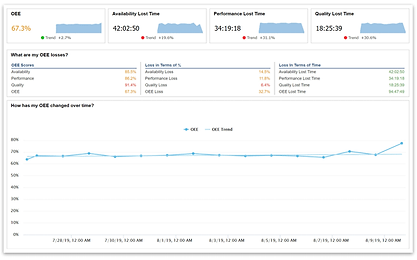

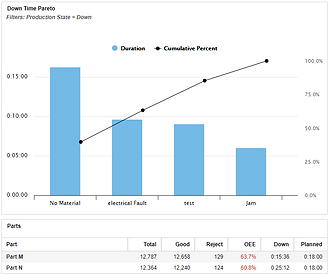

Accurate OEE and downtime data

-

Real-time results on factory display motivates the team

-

Real-time & historical results on web interface

-

Instant customisable web reports.

-

Teams & Labour

-

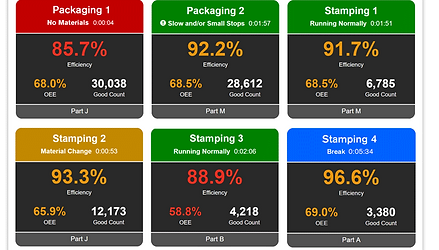

Customisable web dashboards

-

Email / Text Alerting

-

Export to Excel

-

Self deployed in hours, not weeks

-

Super easy to install and use

-

No software to install

-

Tried and tested for over 15 years

-

Bolt-on. This won’t shut your process down

-

A complete solution in a box

-

No ongoing expensive software licence fees

-

Unlimited users

-

90 Day trial

XL provides solutions to common manufacturing problems

Empower and Motivate Operators

Are you doing a lean thinking, lean manufacturing, productivity improvement, six sigma programme?

Having a highly visual workplace is a critical part of a lean or continuous improvement journey, and is key to engaging and motivating your team.

The team and each individual team member must be able to see and understand, at a glance...

-

how they should be going, what is the target?

-

how they are actually going relative to the target? In front or behind?

The scoreboard display gives this real-time information to the operators, helping them to 'Self Measure'.

This in turn can change their behaviour leading to 'Self Improvement', quickly driving the 1st stage of improvement in productivity.

Easy for Operators

If using a system is too hard, it won't get done.

XL makes it easy for the operators to gather accurate reasons for downtime.

No more manual recording. No more fighting with screen savers and passwords.

Simply scan a barcode.

You can also enter additional comments to add more info, context, actions etc to an event

Option available to enter data from a tablet or HMI

Easy for Team Leaders and Management

If trying to find data and getting reports is too hard, it wont get done.

XL makes it easy for anyone to quickly access data and reports to be used in the continuous improvement process.

Problems at a glance

What problems are resulting in the target not being met?

Summary and deep dive downtime and top losses reports

Instant trend charts

What impact are the problem solving actions having on OEE?

Historical trend charts on 100+ KPI's

Instant Visual Factory

Which line needs more support today?

Live Factory Dashboard in your factory, offices, meeting rooms.

Instant Reports

How long should you spend on preparing shift, daily, weekly and monthly reports?

The information you need at your fingertips, using one of the built in dashboards or reports, or, create your own custom reports for anyone in the business.

Easy for Super Users

No script or coding.

Just simply point and click to add new down reasons, add a new part, change a target time and more.

Help tool tips, and videos are built in to assist you.

Point and click Admin changes

Live reporting

Built-in and customisable web based reports enable you to get your information quickly to make continuous improvement decisions. Click this link to see more

XL bolt-ons

XL is a fully self contained system with everything you need built right in.

A suite of Bolt-on solutions allows you to integrate and automate with outside systems.